Straightening Vanes for Precise Flow Conditioning

Precision That Powers Performance

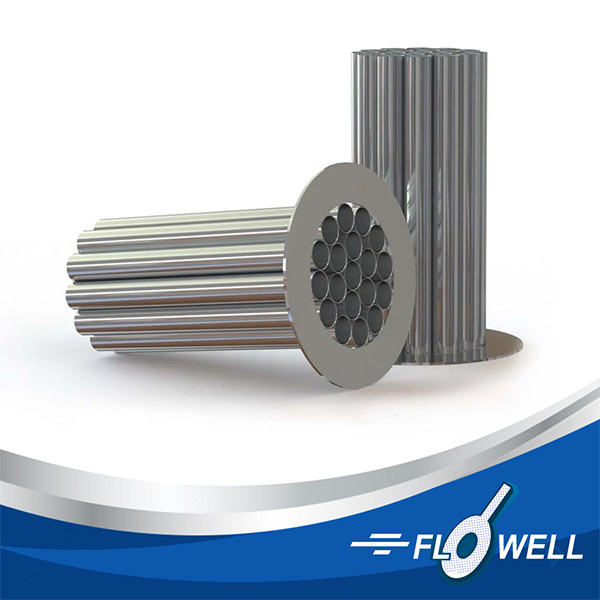

Why straightening vanes matter

At Flowell, our commitment to precision drives everything we do. When it comes to fluid dynamics, the smallest inconsistencies in flow can result in substantial errors in measurement, energy loss, or system inefficiencies. That’s why we manufacture high-performance Straightening Vanes engineered to bring order and stability to your flow profile. These vanes play a critical role in conditioning fluid flow upstream of flow meters—especially orifice plates—where turbulent or distorted flow can compromise accuracy and reliability.

Why Flow Conditioning Matters

From distorted to predictable velocity profiles

In industrial piping systems, flow disturbances are inevitable. Whether caused by upstream valves, elbows, reducers, or tees, these disruptions generate swirls, eddies, and asymmetrical velocity profiles. Left uncorrected, these flow irregularities lead to inaccurate readings and reduced efficiency in downstream measurement devices. Our Straightening Vanes are specifically designed to eliminate these issues by aligning fluid flow into a uniform, axial direction.

The result? You get a clean, stable velocity profile that ensures your flow measurement instrumentation operates at its full potential—delivering dependable data and optimal system performance.

What Is Flow Conditioning?

Flow conditioning is the practice of shaping and stabilizing a fluid’s velocity profile so that downstream meters see repeatable, axisymmetric flow. Straightening vanes are one type of flow conditioner: they mitigate swirl and re-center high-velocity regions after disturbances such as elbows or valves. This reduces profile distortion, improves meter repeatability, and can shorten the upstream straight-run length required by many metering standards.

Flexible Installation Options

Line-mounted vanes

Understanding that no two piping systems are alike, we’ve developed Straightening Vanes to meet a variety of installation needs. Our two primary configurations—line-mounted and flanged—allow you to select the best fit for your infrastructure.

Our line-mounted vanes are ideal for internal installation and secured using set screws that pass through the pipe wall. This method minimizes installation complexity and avoids the need for external bracketing or mounting flanges. It also maintains internal integrity by creating a flush, obstruction-free profile within the pipeline.

Flanged vanes

On the other hand, our flanged vanes are designed to sit snugly between two flanges on the upstream side of an orifice plate or flow meter. This setup provides easy access for maintenance or replacement and ensures a secure, leak-resistant connection every time.

Engineered for Excellence

Material options

We don’t compromise on quality—and neither should you. Our Straightening Vanes are manufactured from premium materials selected for strength, longevity, and resistance to harsh environments. We offer options in:

- Carbon Steel: A robust, economical choice for general-purpose applications.

- 304 Stainless Steel: Ideal for systems exposed to moderate corrosion, humidity, or elevated temperatures.

- 316 Stainless Steel: A superior option for highly corrosive or chemically aggressive environments, offering extended life and performance.

Quality you can specify

Each material is carefully processed and tested to meet stringent metallurgical standards, ensuring that our vanes perform consistently under pressure, over time, and in all operating conditions.

Built to Industry Standards

Standards referenced

Compliance and reliability go hand-in-hand. All our Straightening Vanes are manufactured in accordance with API 14.3 and ISO 5167 standards for flow measurement. These globally recognized specifications define the best practices for ensuring accurate and repeatable results when using differential pressure flow meters such as orifice plates. By adhering to these standards, we ensure that our vanes not only integrate seamlessly with your existing systems but also maintain their performance integrity under varying process conditions. Whether your project requires regulatory compliance or simply demands best-in-class engineering, our products deliver peace of mind.

Measurable Benefits Across Applications

Operational advantages

Adding our Straightening Vanes to your system yields immediate and long-term benefits:

- Enhanced Measurement Accuracy: With more uniform flow, your orifice meters and other instruments provide precise and reliable data.

- Lower Pressure Loss: Optimized flow reduces resistance and turbulence, which in turn minimizes pressure drop and energy waste.

- Improved System Efficiency: Balanced, predictable flow profiles support more stable operations and reduce strain on pumps and downstream components.

- Reduced Maintenance: Clean, well-ordered flow helps protect your instrumentation and piping from unnecessary wear and damage.

These advantages translate into lower operational costs, fewer process interruptions, and more consistent product quality—key outcomes for any process-driven industry.

Applications Across Industries

Our Straightening Vanes are used across a wide range of industries, including:

- Oil and Gas: For accurate custody transfer, production metering, and gas processing.

- Chemical and Petrochemical: Where exact flow measurements are critical for process control and safety.

- Water and Wastewater Treatment: Enhancing the performance of flow meters in variable flow conditions.

- Power Generation: Ensuring efficient fuel and water management.

- Pharmaceuticals and Food Processing: Where hygienic design and flow stability are essential.

Regardless of your industry or application, our solutions are tailored to meet the demands of modern, high-performance systems.

Easy to Customize

Custom engineering support

Every piping system is unique, and we understand that off-the-shelf solutions aren’t always a perfect fit. That’s why we offer custom engineering options to meet your specific requirements. From custom vane geometry and material selection to specialized mounting arrangements or pipe diameters, our team is ready to collaborate with you on tailored solutions that ensure optimal performance and compliance.

Seamless Integration and Support

Documentation & submittals

When you choose Flowell, you’re not just purchasing a component—you’re gaining a partner. Our customer-focused approach means we’re with you at every step of the process. From initial design consultation and sizing recommendations to post-installation troubleshooting, our engineers and technical support team are here to help. We’ll work with your project team, procurement department, or contractors to ensure proper integration and a smooth installation. We also offer detailed documentation, CAD drawings, and compliance certificates to simplify your engineering and validation processes.

Tested for Reliability

Inspection scope

Quality assurance is at the heart of everything we do. Our Straightening Vanes undergo rigorous testing and inspection to verify dimensional accuracy, weld integrity, material hardness, and surface finish.

Optional testing

We also offer non-destructive testing and hydrostatic pressure testing upon request, so you can be confident that your equipment meets all safety and performance expectations.

Future-Proof Your System

Ready for advanced metering

As systems evolve and demand more precision, having a reliable foundation for flow measurement is crucial. Our Straightening Vanes help prepare your system for advanced instrumentation, digital monitoring, and evolving regulatory requirements. With our products in place, you’ll be positioned to scale operations, improve automation, and reduce compliance risk.

Your Trusted Partner in Flow Optimization

We’ve built our reputation on quality, reliability, and technical expertise. Our Straightening Vanes reflect that commitment—offering unmatched performance, easy installation, and long-term value. Whether you’re upgrading an existing system or specifying components for a new project, Flowell is your trusted partner for flow conditioning solutions.

Contact us today to learn how our Straightening Vanes can improve your system’s accuracy, stability, and efficiency. Let’s work together to build systems that perform smarter, longer, and better.

Weight Reference (Selected Sizes)

Selected “Line Model” weights from Flowell Straightening Vanes product sheet. For the complete table and flange-model values, see the PDF.

| Line Size (in) | Line Model Weight (lb) |

|---|---|

| 2 | 2 |

| 4 | 6.5 |

| 8 | 34.5 |

| 12 | 77 |

| 16 | 268 |

| 24 | 688 |

| 36 | 1569 |