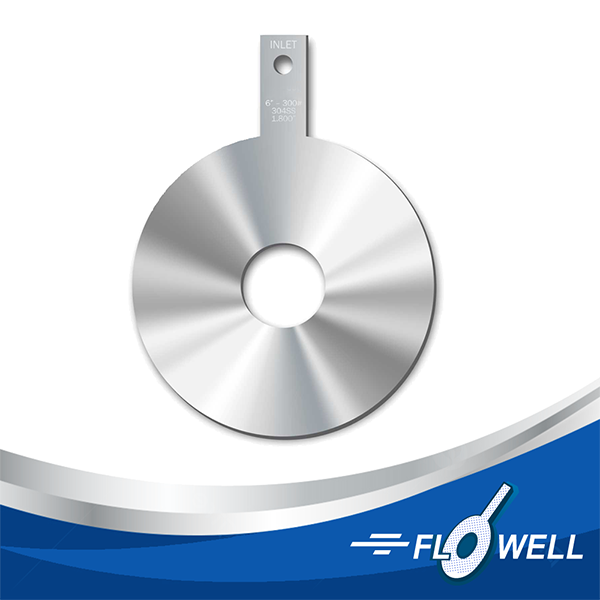

Paddle-Type Orifice Plates

Flowell manufactures paddle-type orifice plates as precision-machined primary elements for dependable differential pressure (DP) flow measurement. Designed for use with orifice flanges, our plates are built using controlled machining and inspection practices to deliver repeatable performance and long service life.

Need help choosing a bore, beta ratio, or plate style? Use our sizing support or contact us to request a quote.

Request a Quote Call 1 (888) 356-9355

Standards and Compliance

We align manufacturing and inspection with widely recognized standards used for orifice plate geometry, flatness, edge preparation, and dimensional tolerance. Our plates are commonly specified to API 14.3, ISO 5167, and ISA RP3.2 depending on the application and metering approach. For a public reference to ISO 5167, see the ISO overview here: ISO 5167.

Standard surface finish is typically 30 RMS to support a clean, sharp orifice edge and predictable flow behavior. If your procedure requires a different finish, we will machine to your specified value and verify it during final inspection.

Materials, Thicknesses, and Sizes

We commonly stock plates from 1/8 inch to 1/2 inch thick in 304 and 316 stainless steel to cover many service conditions and common flange ratings. Standard line sizes range from 1/2 inch to 36 inch, with additional sizes and materials available on request.

When conditions call for alternate alloys (duplex, super duplex, nickel alloys) or coated carbon steels, we can match material selection to process fluid, temperature, corrosion allowance, and pressure class. For special builds, see custom machine work.

Plate Styles and Edge Configurations

We offer the plate styles most commonly specified by measurement professionals:

- Concentric: Standard for clean liquids, gases, and steam where solids are minimal.

- Eccentric: Bore offset to help pass entrained gas or solids and reduce buildup.

- Segmental: Segment opening for higher solids loading or fibrous slurries where self-scouring helps.

- Quadrant-Edge: Radiused inlet for low Reynolds number service to stabilize the discharge coefficient at low flow.

Edge preparation and bevel orientation follow the selected standard and application requirements. We maintain the proper upstream edge and orient bevels correctly relative to flow direction (especially critical for eccentric and segmental designs). If you need a specific bevel angle, quadrant radius, or tighter tolerance on bore roundness and thickness, we can document and deliver to your print.

Sizing, Beta Ratio, and Bore Selection

Correct bore sizing is essential for accuracy, rangeability, and permanent pressure loss. We routinely manufacture bores to support beta ratios (beta = d/D) from approximately 0.2 to 0.75, depending on line size and application constraints.

If you share your operating conditions (fluid properties, pressure and temperature, expected Reynolds number, desired DP, and allowable head loss), we can recommend a bore that balances accuracy with turndown. For projects where installation requirements matter, we can also consider meter run constraints and tap configuration.

Comparing DP primary elements? You may also want to review orifice plates, venturi tubes, and flow nozzles.

Machining Quality and Surface Finish

Our standard 30 RMS surface finish provides a strong balance of edge sharpness and plate flatness for most services. We machine plate faces, bore, and bevel with close control of burrs, then inspect the orifice edge to maintain a crisp entrance condition. Flatness across the sealing surface is controlled to help prevent gasket leakage and maintain parallelism between flange faces.

Identification and Documentation

Each plate can be marked on the paddle tab with critical information such as line size, ANSI rating, thickness, bore diameter, material grade, flow direction, and serial number for traceability. If needed, we can add beta ratio, tag numbers, and calculation basis details, and provide inspection summaries or supporting documentation upon request.

Installation and Orientation

Paddle-type plates are designed for insertion between matched orifice flanges. We can include flow-direction arrows and orientation marks. For eccentric and segmental bores, proper orientation is critical relative to solids or gas pockets; we can supply orientation guidance to simplify field work.

Typical Applications

- Oil and Gas: Natural gas metering (with appropriate meter runs), fuel gas, produced water, flare and vent monitoring.

- Refining and Petrochemical: Liquid hydrocarbons, steam balancing, utility systems, process gases.

- Power Generation: Boiler feedwater, condensate, auxiliary steam, and air service.

- Water and Wastewater: Raw water intake, treated effluent, chemical dosing, and aeration air.

- Pulp and Paper, Mining, Food: Services where segmental or eccentric plates help maintain signal quality with solids.

Ordering Information

To ensure a perfect fit, include the following in your request:

- Size (nominal pipe size)

- ANSI rating (to match your orifice flange class)

- Thickness (1/8 inch to 1/2 inch standard; others on request)

- Bore diameter (or beta ratio / target flow range)

- Material (304 or 316 stainless standard; others on request)

Helpful additions include plate style (concentric, eccentric, segmental, quadrant-edge), flow direction, tap style, operating conditions, and any special marking or documentation requirements.

If you prefer, we can size the bore from your process data and align the recommendation with your specified standard.

Customization, Handling, and Lifecycle

Orifice plates are measurement instruments and sealing components. Protect the upstream edge from nicks, store plates in sleeves or cases, and inspect edges for wear or rounding during maintenance. If process conditions change significantly (fluid properties, solids loading, turndown requirements), consider a bore re-evaluation to maintain accuracy and signal strength.

Paddle-Type Orifice Plate FAQs

Request a Quote

Ready to order or replace a plate? Send your specs to Flowell and we’ll confirm the right configuration for your service and standards.