Studding Outlets — Secure Vessel & Tank Connections

Studding Outlets are a crucial component in the oil and gas industry. Designed to be installed inside or outside of vessels and tanks, studding outlets from Flowell are a reliable and cost-effective solution for connecting auxiliary piping. These specialized flanges have a flat design, can be pressure rated, and offer a low profile for minimal disturbance in piping systems. As a leading provider of custom machining and flow measurement products for the oil and gas industry, Flowell is here to provide you with in-depth information on studding outlets and offer a free quote for your specific needs. Read on to learn more about the definition, common applications, and features of studding outlets from Flowell.

When it comes to industrial piping systems, the design and components used are of utmost importance to ensure the efficiency, safety, and reliability of the entire system. One crucial component that is commonly utilized in the installation and connection of pipes, vessels, and tanks is the studding outlet. Studding outlets, also known as pad flanges, are specialized types of flanges that are designed for secure attachment and connection to tanks or pipes, and they play a significant role in a wide range of industrial applications. In the following comprehensive guide, we will delve into the various aspects of studding outlets, including their design, applications, features, and the important role they play in industrial piping connections.

What are Studding Outlets used for?

Studding outlets, as the name suggests, are specifically designed for the purpose of providing a reliable and economical means of connection to tanks or pipes in industrial settings. They are commonly used in the oil and gas, petrochemical, chemical, and other industrial sectors. These outlets can be installed both inside and outside of vessels or tanks, and their versatile design allows for a wide range of applications in different industrial settings. The flexibility in installation, whether inside or outside, makes them a preferred choice in various piping and equipment configurations.

The unique curvature of the studding outlet is a defining feature that allows it to seamlessly fit the shape of the shell, head, or pipe to which it is being connected. This customized and contoured design is crucial in ensuring a perfect fit and alignment, which is essential for the overall integrity and functionality of the piping or vessel to which it is being attached. The ability of the studding outlet to conform to the specific shape and curvature of the connection point is instrumental in preventing any potential stress points or uneven distribution of forces, which in turn enhances the overall safety and performance of the system.

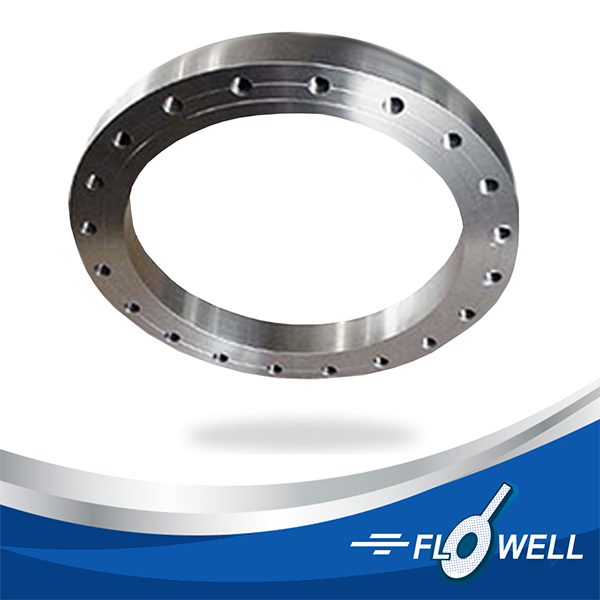

Studding outlet flanges are equipped with multiple stud holes, which are strategically positioned to facilitate the secure and robust attachment of the outlet to the connected pipe, vessel, or tank. The presence of these multiple stud holes allows for a reliable and stable connection, effectively distributing the load and ensuring the integrity of the overall assembly. This secure attachment is a critical requirement in industrial applications, and the studding outlet’s design is optimized to meet this demand, providing a high degree of strength and stability in the connection.

One of the key characteristics of studding outlet flanges is their specialized and flat design, which sets them apart from standard flanges. This unique design is tailored to meet the specific requirements of piping systems, particularly in cases where the connection of auxiliary piping is necessary. The flat profile of the studding outlet flange enables a streamlined and space-efficient connection, making it an ideal choice for applications where a low-profile design is preferred. Additionally, these flanges can be manufactured to be pressure rated, further enhancing their versatility and suitability for a wide range of industrial processes and operating conditions.

Studding outlets, or pad flanges, are a vital component in industrial piping systems and find widespread use in a diverse set of applications. They are commonly utilized in the connection of auxiliary piping, including the installation of pressure gauges, temperature sensors, or other instruments. Additionally, their flat and pressure-rated design makes them ideal for connecting small-bore or instrument-sized piping in various industrial processes. The ability of studding outlet flanges to facilitate a secure and reliable connection for auxiliary piping, even in limited spaces, highlights their importance in enhancing the functionality and efficiency of industrial systems.

Studding Outlets For Curved Surfaces

Studding outlets are specifically designed to accommodate and connect to curved surfaces, making them a preferred choice in piping and equipment configurations where standard connections may not be suitable. The contoured design of the studding outlet allows for a seamless and perfect fit to the specific curvatures of the connected shell, head, or pipe, ensuring a uniform and stable connection. This unique capability is instrumental in addressing the challenges posed by curved surfaces, and it further underscores the importance and relevance of studding outlets in industrial piping applications.

Additional Studding Outlet Features

Reinforcement and Secure Attachments

In addition to their contoured design, studding outlets are reinforced for added strength to ensure the secure attachment of auxiliary piping or other components. The presence of multiple stud holes and the flat, pressure-rated design of the studding outlet flange are all contributing factors to the robust and stable connection it offers. By providing a reliable and secure attachment, studding outlets play a critical role in the overall integrity and safety of industrial piping systems. Whether it’s for the connection of small-bore piping or larger vessels, the reinforcement and secure attachment features of studding outlets are essential for withstanding operational pressures and ensuring the long-term performance of the system.

Low Profile Design and Piping Connections

The low profile design of studding outlets, in combination with their pressure-rated and flat configuration, makes them highly suitable for a wide range of piping connections. These outlets offer a compact and space-efficient solution for connecting auxiliary piping, and their pressure-rated capability ensures that they can be seamlessly integrated into the main piping system while meeting necessary safety and performance standards. Whether it’s in the installation of pressure gauges, flow measurement instruments, or other auxiliary components, the low profile design and robust construction of studding outlets make them a preferred choice for diverse piping connections in industrial settings.

Installation Inside Vessels and Tanks

When it comes to the installation of studding outlets, particularly inside vessels and tanks, their specialized design and reinforced construction are of particular significance. The ability of studding outlets to be installed inside the vessels or tanks, while ensuring a secure and reliable connection, highlights their adaptability to a wide range of installation requirements. Whether it’s for connecting to the internal surfaces of pressure vessels, tanks, or process equipment, the design and construction of studding outlets are geared towards providing a strong and durable connection, thereby contributing to the overall safety and performance of the installed systems.

Customized for Industrial Applications

In the realm of industrial applications, the importance of customized and specialized components cannot be overstated. Studding outlets, with their unique design features and reinforced construction, are an integral part of the toolkit for addressing the specific and diverse connection needs in industrial settings. From the connection of small-bore piping to the installation of instruments and auxiliary components, studding outlets offer a reliable and efficient solution that is tailored to meet the distinct requirements of various industrial processes. Their ability to be customized and manufactured in accordance with specific design and pressure rating specifications further solidifies their role in supporting the seamless and safe operation of complex industrial systems. Contact us!

Whether in the oil and gas, chemical, petrochemical, or any other industrial sector, the choice of studding outlets plays a crucial role in the overall performance, safety, and reliability of piping and equipment installations. The specialized design, contoured fit, low profile, and reinforcement features of studding outlets make them an indispensable component in a wide range of industrial applications. It is essential for industrial facilities and engineering professionals to have access to high-quality and precision-engineered studding outlets to ensure the seamless and efficient operation of their piping systems and equipment. In this regard, partnering with a trusted and experienced manufacturer and supplier of studding outlets is paramount to meeting the specific and demanding connection needs of industrial installations.