Products

Flow Measurement Products

Flowell manufactures flow measurement products designed for accurate, repeatable differential pressure (DP) flow measurement in demanding service. Our lineup supports measurement of gas, liquid, and steam and is commonly used in oil and gas, chemical processing, power generation, water and wastewater, and industrial facilities.

Use this page as your hub to compare product categories, then click into any item for specifications, configuration options, and application guidance. If you need help selecting the right primary element or accessory, use our sizing support or contact us for a quote.

How to Choose the Right Flow Measurement Product

Choosing the right product depends on your service conditions, installation constraints, and allowable pressure loss. Here’s a simple way to narrow it down:

- Need low permanent pressure loss? Consider venturi tubes.

- Need a standards-based, cost-effective DP primary element? Consider orifice plates or paddle-type orifice plates.

- High velocity or severe service? Consider flow nozzles.

- Need a complete meter run? Explore meter tubes and straightening vanes.

- Protect instruments and improve reliability? Add strainers, condensate chambers, and bleed rings.

Need custom materials, non-standard dimensions, or special machining? We support special builds through custom machine work.

Select a category of our flow measurement products here:

Need Sizing Help?

Send your line size, media, pressure/temperature, and target flow range. We’ll recommend the best product and configuration for your application.

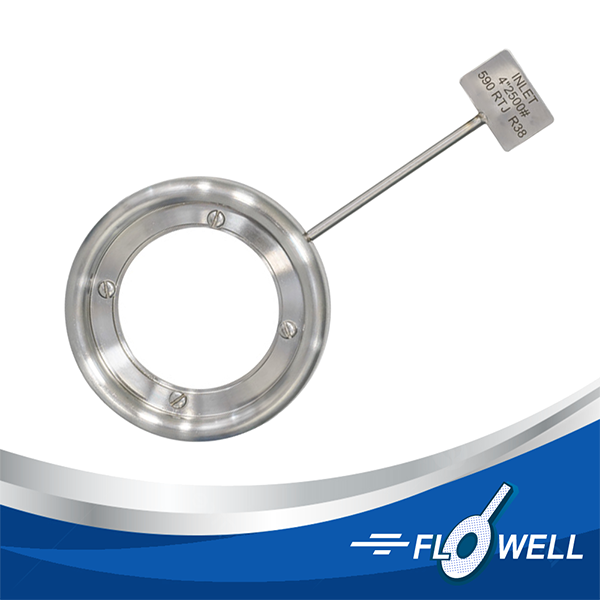

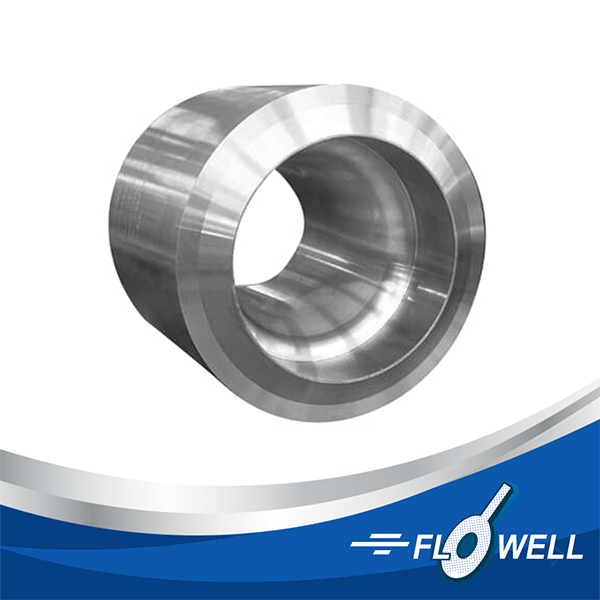

RTJ Plate Holders

RTJ Plate Holders Meter Tubes

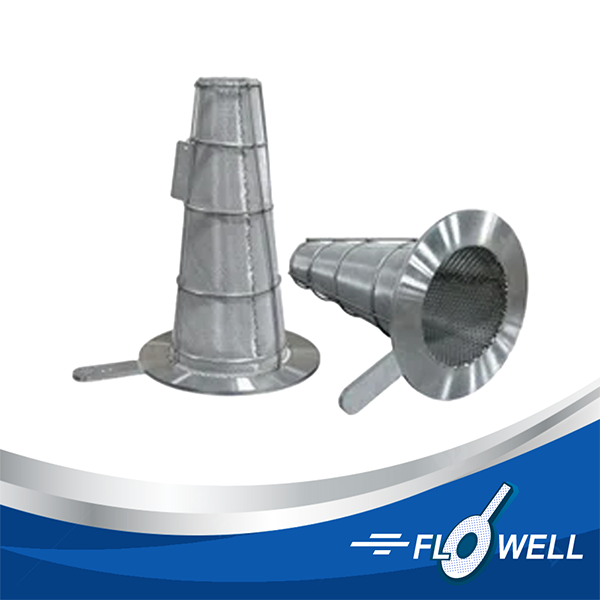

Meter Tubes Strainers

Strainers

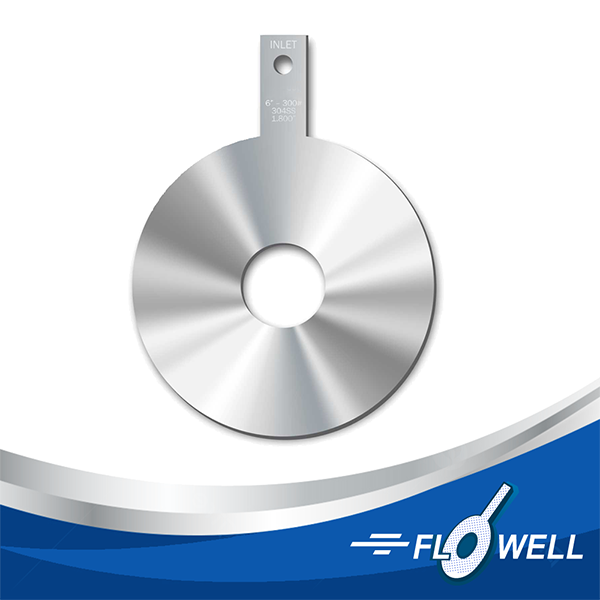

Figure 8 Spectacle Blinds

Figure 8 Spectacle Blinds Paddle Spacers and Blinds

Paddle Spacers and Blinds Studding Outlets

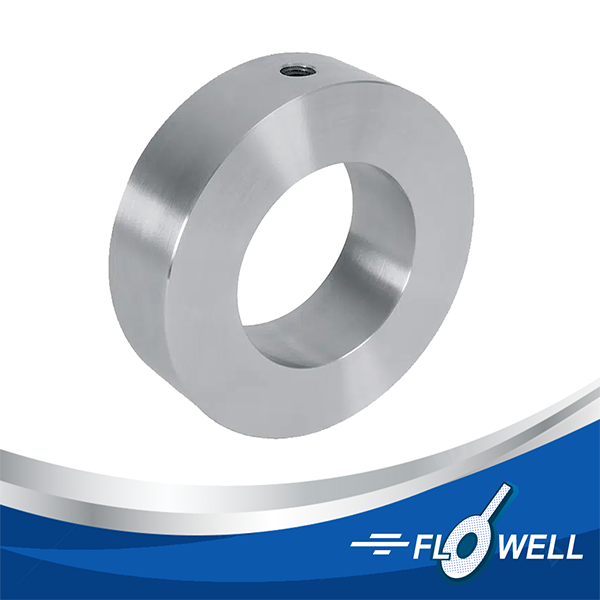

Studding Outlets Bleed Rings

Bleed Rings Condensate Chambers

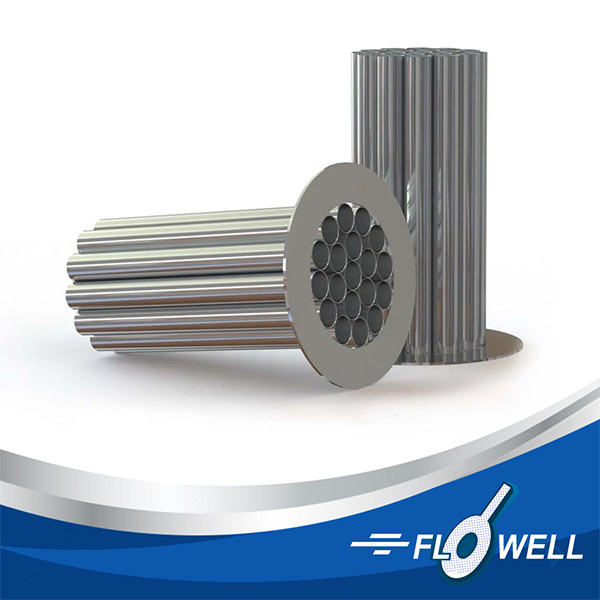

Condensate Chambers Straightening Vanes

Straightening Vanes Flow Nozzles

Flow Nozzles Venturis

Venturis Paddle-Type Orifice Plates

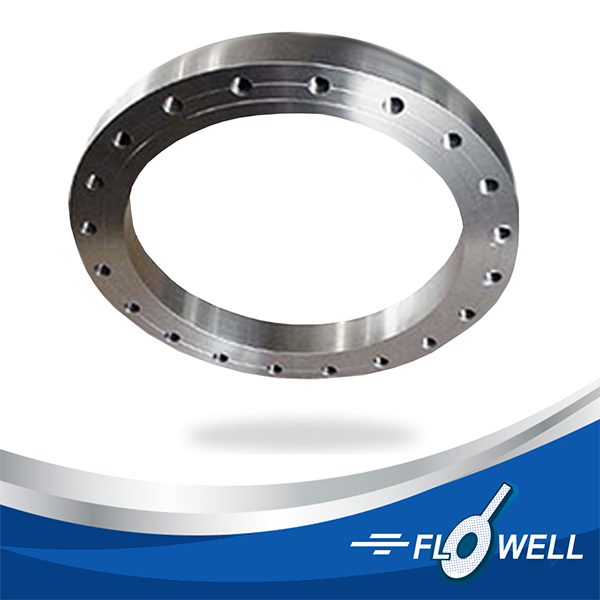

Paddle-Type Orifice Plates Orifice Flange Union

Orifice Flange Union