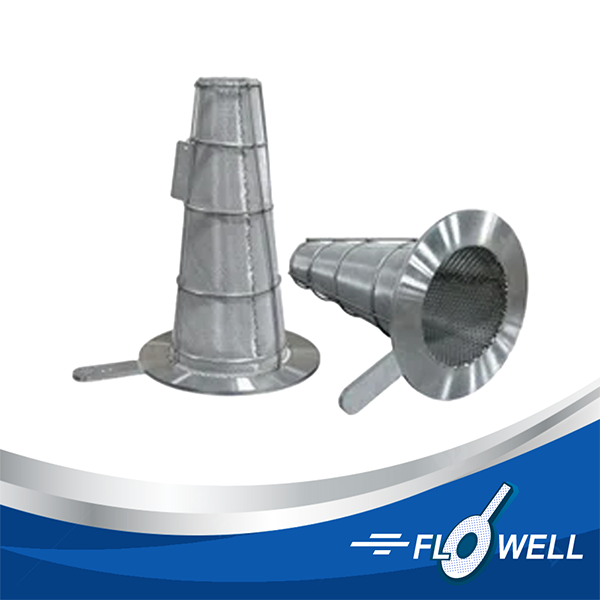

High-Performance Carbon & Stainless Steel Strainers

At Flowell, we proudly offer a complete line of high-quality carbon & stainless steel strainers designed to meet the diverse needs of industries like oil and gas, chemical, petrochemical, water treatment, and more. With over 30 years of expertise in flow measurement and custom machining, we know how crucial it is to maintain reliable system operations. That’s why our strainers are built with precision and durability in mind.

Our strainers using only the best materials, available in sizes from 1″ to 24″, with open area ratios ranging from 100% to 300%. Whether you need fine mesh filtration or heavy-duty particle separation, we offer products tailored to your exact specifications.

Strainers protect downstream equipment by removing debris, scale, sediment, and other particulates from process fluids. Poor filtration can lead to equipment damage, reduced efficiency, and costly downtime. That’s why every strainer we produce is engineered and rigorously tested to perform in even the harshest industrial environments.

Our carbon steel and stainless steel strainers are designed to provide long-term durability and high-performance filtration under pressure. We use a range of liner or mesh wire sizes to customize filtration, helping you optimize system integrity without sacrificing flow rates.

Why Strainers are Essential for Process Efficiency

Strainers play a critical role in ensuring system reliability by maintaining clean process fluids. They help prevent costly damage to equipment and reduce operational downtime.

Durable Carbon Steel Strainers for Cost-Effective Filtration

Our carbon steel strainers offer a cost-effective solution for many industrial applications, particularly when corrosion resistance is not a primary concern. Carbon steel delivers the toughness and durability required for high-pressure systems, and it’s often chosen for its structural integrity and lower upfront investment.

Applications for Carbon Steel Strainers

These strainers are perfect for:

- General-purpose filtration in oil & gas pipelines

- Non-corrosive fluid handling

- Water and steam applications

- Industrial process lines with high temperatures and pressures

To enhance corrosion resistance and extend service life, we offer coatings like epoxy, zinc plating, and primer options, depending on your operational needs.

Stainless Steel Strainers for Superior Corrosion Resistance

When corrosion resistance is critical, stainless steel strainers are the superior choice. These models are designed for longevity, minimal maintenance, and superior strength, making them ideal for applications in aggressive chemicals, high-purity liquids, and food-grade environments.

Applications for Stainless Steel Strainers

Our stainless steel strainers are commonly used in:

- Chemical and petrochemical processing

- Pharmaceutical production

- Food and beverage manufacturing

- Offshore and marine environments

- Corrosive wastewater systems

We offer 304 and 316 stainless steel grades, both of which provide excellent resistance to oxidation and chemical degradation. For demanding applications, such as those involving chlorides or extreme temperatures, we can discuss other stainless alloys to meet your needs.

Customizable Carbon & Stainless Steel Strainers for Every Need

Our strainers offer a variety of customization options. We provide configurations with open areas from 100% to 300%, depending on your system’s pressure drop tolerances and desired debris-holding capacity.

Tailored Filtration for Your Specific Requirements

By using different liner or mesh wire sizes, we tailor filtration to your exact requirements—from coarse separation to fine mesh filtering of minute contaminants. Whether you need a 100-micron mesh or something more robust, our engineering team will help design the right strainer for your application.

Customization options include:

- Mesh size (measured in microns or mesh count)

- Strainer type: basket, Y-type, tee-type, or cone strainers

- End connections: flanged, threaded, or weld-end

- Drain and blow-off ports

- Lifting lugs, support legs, and other accessories

Built to Meet Industry Standards for Maximum Performance

Our strainers are built to meet relevant industry standards like ASME B31.3, ANSI flange specifications, and other applicable codes. We test all our strainers for pressure containment and leak integrity before they leave our facility.

You can rely on us for:

- High-pressure ratings up to ANSI Class 2500

- Full traceability of materials

- Hydrostatic and pneumatic testing

- Optional certifications such as NACE compliance or PED/CE marking

Our team can provide data sheets, CAD drawings, or 3D models to assist with your system design, procurement process, or technical submittal package.

Strainers Sized for Your Application—From 1″ to 24″

We manufacture strainers in sizes ranging from 1 inch to 24 inches, ensuring a perfect fit for both small systems and large-scale operations. Whether you’re outfitting a pilot plant or upgrading a major process facility, we can scale our products to meet your infrastructure.

We also accommodate special design requests for sizes outside the standard range or unique connection and geometry requirements. Contact us today, and we’ll be happy to provide solutions and guidance.

Reliable Service and Support Every Step of the Way

At Flowell, we provide more than just strainers—we build lasting relationships with our clients through dependable service and technical support. Our experienced team is here to help you select the right product, answer your questions, and ensure flawless performance once your strainer is installed.

Need a quick turnaround? We understand that time is crucial. That’s why we keep many standard items in stock and offer expedited fabrication services for custom builds.

From your initial inquiry to post-installation support, we’re with you every step of the way.

Why Choose Flowell Strainers?

Here’s what sets our strainers apart:

- Material Versatility: Choose from carbon steel or stainless steel to suit your process needs.

- Flexible Sizing: We offer sizes ranging from 1″ to 24″, with custom sizes available.

- Open Area Options: Optimize flow and filtration with open areas from 100% to 300%.

- Custom Fabrication: Tailor mesh size, end connections, and fittings to your specific needs.

- Durability: Built for harsh environments, high-pressure systems, and long service life.

- Industry Expertise: Over 30 years of experience in industrial flow solutions.

- Responsive Support: Our team is dedicated to providing timely, knowledgeable support.

Get Started with Flowell Today

If you’re looking to enhance your system’s efficiency, extend equipment lifespan, and reduce downtime, our carbon & stainless steel strainers are the solution. We’re ready to provide a quote, answer technical questions, or design a custom solution tailored to your needs.

Contact us today to explore our strainer options or request a product catalog. At Flowell, we deliver precision-engineered solutions that keep your operations flowing smoothly.