Flow Nozzles Manufactured in Tulsa, OK | ASME & ANSI-Compliant

Flowell Corporation manufactures precision ASME MFC-3M flow nozzles, differential pressure flow nozzles, and high-accuracy flow measurement components for steam, gas, and liquid systems. As a U.S.-based flow nozzle manufacturer in Tulsa, OK, we supply flow nozzles nationwide for power generation, oil & gas, chemical processing, water & wastewater, and other industrial applications.

Our Flow Nozzles are designed with precision, durability, and industry compliance in mind. Each nozzle is manufactured in strict accordance with ASME MFC-3M and ANSI B31 standards, ensuring dependable performance in even the most demanding applications. Whether you are measuring high-velocity steam, gas, or liquid flow, our nozzles provide accurate differential pressure measurement with long service life and minimal maintenance requirements.

Why Choose Flowell Flow Nozzles?

We understand the importance of accuracy and reliability in differential pressure (DP) flow measurement systems. That’s why we’ve engineered our Flow Nozzles to withstand extreme conditions while maintaining a high degree of measurement integrity. Our standard construction uses stainless steel, offering excellent resistance to corrosion, erosion, and thermal stress. For specialized environments, we also offer a variety of corrosion-resistant materials upon request.

These flow nozzles are ideal for industries such as power generation, petrochemical, oil and gas, and water treatment, where long-term stability and durability are essential.

Compliance with Global Standards

Every Flowell Flow Nozzle is manufactured in accordance with:

- ASME MFC-3M – Measurement of Fluid Flow in Closed Conduits

- ANSI B31 – Code for Pressure Piping

This ensures full compatibility with recognized global engineering practices. Our nozzles integrate seamlessly into existing piping systems, conform to regulatory requirements, and reduce the need for custom adaptations or field modifications. To learn more about the ASME MFC-3M standard used in our manufacturing process, visit the official ASME resource: ASME MFC-3M Flow Measurement Standard.

Material Versatility

Our standard material is 316 stainless steel, selected for its robustness and resistance to a wide range of corrosive environments. However, we know that not all applications are alike. That’s why we offer alternative materials, including:

- Hastelloy

- Inconel

- Monel

- Duplex Stainless Steel

- Titanium

These material options allow our customers to confidently use Flowell Flow Nozzles in high-temperature, high-pressure, or highly corrosive systems.

Flow Nozzle Styles

We offer four primary nozzle configurations to suit a range of installation and operational requirements. Each style is precisely machined and inspected to ensure performance and consistency.

1. Flanged Style

Our Flanged Flow Nozzle is designed for straightforward installation between standard pipe flanges. This style is ideal for customers seeking an easy-to-maintain and replaceable solution. The flanged configuration allows quick access for inspection or cleaning and offers flexibility during pipeline upgrades or retrofits.

- Compatible with ANSI and DIN flange standards

- Sizes from ½” to 24″ and larger upon request

- Custom pressure tap configurations available

2. Flanged Throat Tap

The Flanged Throat Tap Flow Nozzle takes the convenience of the standard flanged model a step further by incorporating the downstream pressure tap directly into the nozzle body. This integrated design simplifies piping layouts and minimizes potential leak points or misalignments.

- Streamlined installation with fewer components

- Reduced installation errors due to integral design

- Ideal for systems where space and accuracy are critical

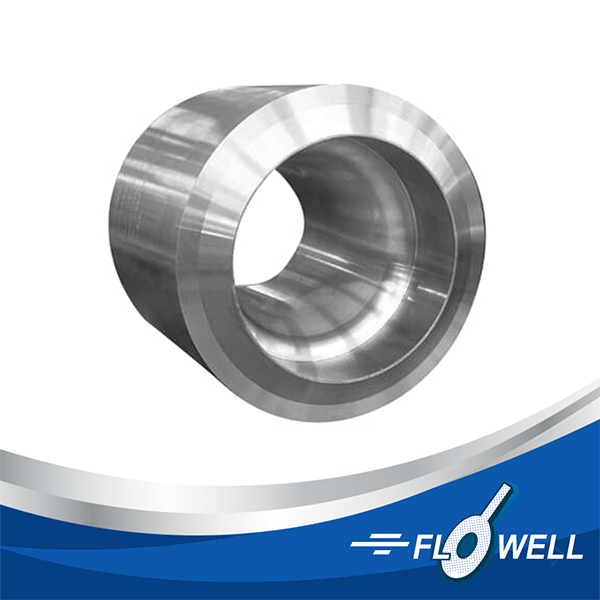

3. Weld-In Style

Our Weld-In Flow Nozzle is intended for permanent installations where optimal sealing and long-term stability are paramount. A machined ring on the outside diameter of the nozzle allows it to be welded directly between two pipe sections. The nozzle body resides entirely within the pipe, preserving a clean flow profile and minimizing flow disturbances.

- Fully contained within the piping

- Suited for high-pressure, high-temperature service

- Excellent choice for power plants, refineries, and chemical processing

4. Holding Ring Style

The Holding Ring Flow Nozzle offers a non-intrusive installation method, especially valuable in systems where external welding is not practical. The nozzle is inserted within the pipe and held in place with an internal ring and welded pins that pass through the pipe wall. This design provides a secure, sealed fit without requiring extensive external modifications.

- Easy to install in existing pipelines

- Secure mounting with minimal intrusion

- Often used in retrofit projects or custom layouts

Flow Nozzles vs. Venturi Tubes vs. Orifice Plates

Flow nozzles are one of several common differential pressure primary elements. The table below compares Flow Nozzles to Venturi Tubes and Orifice Plates for typical industrial applications.

| Device | Relative Accuracy | Permanent Pressure Loss | Typical Use |

|---|---|---|---|

| Flow Nozzle | High | Low | High-velocity steam, gas, and liquids in harsh service |

| Venturi Tube | Very High | Very Low | Clean fluids, large line sizes, low energy loss systems |

| Orifice Plate | Medium | High | General-purpose, low initial cost applications |

Flow nozzles offer a strong balance of accuracy, durability, and low permanent pressure loss, especially in high-velocity and high-temperature applications where orifice plates may wear quickly.

Technical Specifications

- Standards: ASME MFC-3M, ANSI B31; designed to align with ISO 5167 nozzle practices

- Line Sizes: ½” to 48″ and larger upon request

- Beta Ratios: Typical range from 0.2 to 0.8 (application dependent)

- Pressure Classes: Designed for standard ANSI class ratings; higher ratings available upon request

- Media: Steam, natural gas, process gas, clean and process liquids

- Mounting Styles: Flanged, Flanged Throat Tap, Weld-In, Holding Ring

Flow nozzles can be supplied as standalone primary elements or as part of an engineered flow measurement package alongside meter tubes, orifice plates, and related accessories.

Benefits of Using Flowell Flow Nozzles

When you choose our flow nozzles, you benefit from a solution built for long-term precision and ease of use. Key advantages include:

- High Accuracy and Repeatability: Smooth contours and engineered geometry deliver excellent flow characteristics and predictable pressure differentials. Flow nozzles are especially effective in high-velocity and non-laminar flow applications where other devices might struggle to maintain accuracy.

- Low Permanent Pressure Loss: Our nozzles are designed to optimize pressure recovery downstream, minimizing permanent pressure loss. This results in better energy efficiency and lower operating costs over the long term.

- Minimal Maintenance: With no moving parts and rugged construction, our nozzles require virtually no maintenance once installed. This reduces downtime and total cost of ownership—critical for continuous process operations.

- Long Service Life: The materials and construction methods we use allow our Flow Nozzles to last for decades, even under harsh conditions. Erosion resistance, thermal tolerance, and corrosion resistance are engineered into every design.

Applications Across Industries

Our Flow Nozzles are used across a broad spectrum of industries and processes, including:

- Power Generation: High-pressure steam flow measurement for turbines, boilers, and auxiliary systems

- Oil & Gas: Gas lift, flare measurement, pipeline balancing, and process control

- Chemical Processing: Aggressive fluids and demanding process conditions

- Water & Wastewater: Plant influent/effluent monitoring and process water control

- Pharmaceutical & Food: Applications requiring cleanliness and stainless-steel construction

We can also provide specialized configurations for high-viscosity fluids, multiphase flow, or pulsating systems.

Custom Engineering and Support

We understand that off-the-shelf solutions do not always meet every need. That’s why we offer engineering support for custom applications. We are ready to assist you from concept to installation, including:

- CAD drawings and modeling

- Pressure drop and sizing calculations

- Tap and manifold layout recommendations

- Material selection and certification documentation

Whether you need a modified bore profile, unique tap arrangement, or specialty material, our in-house engineering team is equipped to help you design and specify the right nozzle for your project.

Testing and Quality Assurance

Every Flowell Flow Nozzle goes through stringent quality control procedures, including:

- Dimensional inspection using precision metrology

- Material traceability and certification

- Weld inspection (for welded styles)

- Hydrostatic and/or pressure testing as required

- Optional NDT (non-destructive testing) services upon request

Our commitment to quality ensures that each nozzle we ship performs exactly as intended in your system.

Installation and Integration

We provide installation guidelines, flange torque specifications, and best practices for tap alignment and signal conditioning. Our team is available to consult with your engineering or maintenance staff to ensure smooth integration into your existing flow measurement system.

We also work with major instrumentation providers to ensure compatibility with differential pressure transmitters, manifolds, and flow computers, helping you create a complete and reliable DP flow measurement solution.

Frequently Asked Questions About Flow Nozzles

What is a flow nozzle used for?

A flow nozzle is a differential pressure primary element installed in a pipeline to create a known pressure drop. By measuring this pressure differential, the flow rate of steam, gas, or liquid can be accurately calculated.

How do flow nozzles compare to Venturi tubes and orifice plates?

Flow nozzles provide higher accuracy and lower permanent pressure loss than orifice plates, with a more compact footprint and lower cost than most Venturi tubes. They are especially well suited for high-velocity, high-temperature service.

Which standards do Flowell flow nozzles meet?

Flowell flow nozzles are manufactured in accordance with ASME MFC-3M and ANSI B31 piping codes and are designed to align with common global practices such as ISO 5167 nozzle designs.

Do you ship flow nozzles outside Oklahoma?

Yes. Flowell manufactures flow nozzles in Tulsa, Oklahoma and supplies customers across the United States and internationally.

Can you help size and select the right flow nozzle?

Absolutely. Our engineering team can review your process conditions, line size, pressure, and media to recommend the correct nozzle style, beta ratio, and material for your application.

Let’s Get Started

Whether you are designing a new system or upgrading an existing one, our Flow Nozzles provide a dependable, standards-compliant, and efficient solution for flow measurement. Contact us today for a consultation or quote and let us help you determine the best nozzle configuration and material for your application.