Flow Meter Turndown Ratio Explained: Why It Matters?

In the world of industrial measurement, few topics are as critical yet often misunderstood as the flow meter turndown ratio. Understanding how this ratio affects performance, accuracy, and meter selection can be the difference between efficient operation and costly inefficiencies. In this blog, we’ll break down the flow meter turndown ratio explained from its basic definition to its practical impact on system design, accuracy, and reliability. Whether you work with oil, gas, water, or chemical applications, grasping this concept will help ensure your system runs smoothly across varying flow conditions.

Flow Meter Turndown Ratio Explained: The Core Concept

At its most basic, the turndown ratio, also known as rangeability, defines the range over which a flow meter can accurately measure flow. It is typically expressed as the ratio of the maximum flow rate to the minimum measurable flow rate within the meter’s stated accuracy limits. For example, if a flow meter can measure flows from 100 gallons per minute (GPM) down to 10 GPM while maintaining its accuracy specification, it has a turndown ratio of 10:1.

This ratio is crucial because most flow processes don’t operate at a single, constant rate. Instead, flow can vary widely depending on process demand, time of day, or product batch size. A meter with a limited turndown ratio may perform well at full flow but lose accuracy or even fail to register at low flow conditions. In contrast, a meter with a high turndown ratio provides more flexibility and reliability over a wide operating window.

High turndown ratios are especially valuable in systems with variable loads or batch processes. For instance, in oil and gas production, a pipeline may experience fluctuating flow rates due to well output changes or intermittent operations. Having a meter that maintains accuracy across these variations ensures consistent measurement and control.

Flow Meter Turndown Ratio Explained: Accuracy & Rangeability

The turndown ratio directly influences measurement accuracy. Every flow meter type has an inherent design limitation, its ability to maintain accuracy as flow deviates from the calibrated range. Manufacturers typically specify accuracy as a percentage of reading (% of actual flow) or percentage of full scale (% of maximum calibrated flow).

Meters rated for accuracy as a percentage of reading tend to maintain better performance at low flows compared to those rated as a percentage of full scale. For example, if a meter has an accuracy of ±1% of reading, it will remain equally accurate whether the flow is high or low. However, a meter with ±1% of full-scale accuracy will see its relative error increase as flow decreases.

Understanding this distinction is key to proper meter selection. If your process has a narrow, consistent flow rate, a meter with a smaller turndown ratio may suffice. But if your system experiences wide swings in flow, selecting a technology with a high turndown ratio and percentage-of-reading accuracy will ensure better performance.

Flow Meter Turndown Ratio Explained: DP, Ultrasonic, Coriolis

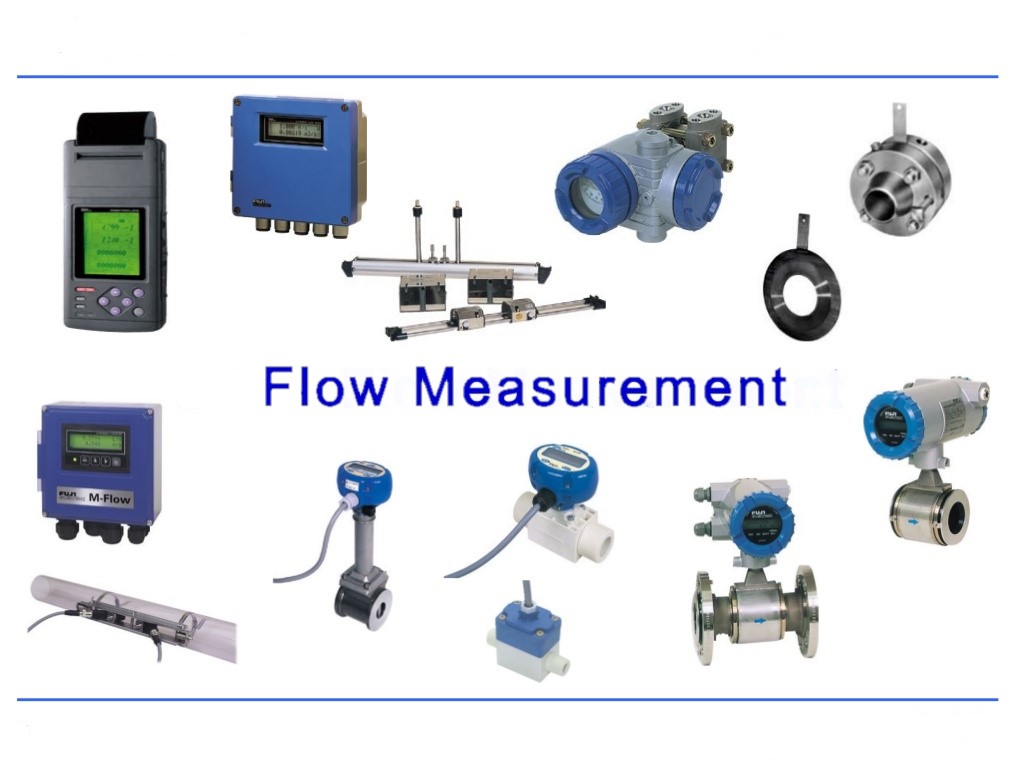

Different flow measurement technologies have different inherent turndown capabilities:

Differential Pressure (DP) Flow Meters: DP flow meters, including orifice plates and Venturi tubes, operate based on the square root relationship between flow and pressure differential. This means small errors in pressure measurement become amplified at lower flows, limiting practical turndown to about 3:1 to 5:1 for orifice plates, and up to 10:1 for advanced DP transmitters with smart electronics.

Ultrasonic Flow Meters: Ultrasonic meters measure flow using the transit-time or Doppler effect of sound waves through the fluid. They can achieve turndown ratios as high as 50:1 or even 100:1 in some cases. Because they have no moving parts and rely on electronic signal processing, ultrasonic meters are ideal for applications with variable or intermittent flow conditions, such as custody transfer and water distribution systems.

Coriolis Flow Meters: Coriolis meters are considered the gold standard for accuracy and rangeability. They directly measure mass flow using fluid inertia within vibrating tubes. Turndown ratios of 100:1 are common, and accuracy remains excellent across a wide flow spectrum. Although they tend to be more expensive and sensitive to fluid density and vibration, their superior performance makes them well-suited for oil and gas, chemical processing, and other high-value applications.

Each technology offers a tradeoff between cost, complexity, and turndown performance. Selecting the right type depends on your process’s flow variability, fluid type, and precision requirements.

Flow Meter Turndown Ratio Explained: Reynolds & Viscosity Effects

An often-overlooked aspect of turndown performance involves fluid dynamics, particularly the Reynolds number and viscosity effects. The Reynolds number quantifies the flow regime, laminar, transitional, or turbulent, within a pipeline. For many meters, accuracy depends on maintaining a stable, fully developed turbulent flow profile.

At very low flow rates (and hence low Reynolds numbers), the flow can become laminar, which changes how the fluid interacts with the sensing mechanism. For example, a DP meter calibrated under turbulent conditions may read inaccurately under laminar flow. Similarly, viscous fluids such as heavy oils or slurries can exaggerate these effects, narrowing the effective turndown ratio.

Viscosity also impacts meters differently depending on design. Coriolis meters tend to handle viscosity well since they measure mass directly, while turbine meters may suffer mechanical drag that skews readings at low flows. Ultrasonic meters, depending on signal type, may also see degraded performance in high-viscosity or aerated fluids.

For engineers and operators, understanding how fluid properties interact with the meter’s physics is critical when defining practical rangeability. Laboratory-stated turndown ratios are idealized values; they assume clean, steady flow and constant conditions. Real-world applications often require a safety margin to account for these variations.

Choosing Meters for Variable Loads and Batch/Continuous Duty

Flow systems in industrial environments often experience both steady-state and dynamic operating modes. The choice of flow meter should align with how frequently and drastically your flow conditions change.

Batch processes, for instance, require meters that can start and stop frequently while maintaining high accuracy at low startup flows. Continuous processes, on the other hand, may operate steadily for long durations but still demand a meter that can handle occasional fluctuations without recalibration.

The turndown ratio becomes a critical selection parameter in both cases. For example, a plant that measures both startup purge flows and full production rates may see variations of 50:1 or more. A DP meter in that application could underperform, while a Coriolis or ultrasonic meter would provide reliable readings across the range.

Additionally, environmental conditions such as temperature, pressure, and gas composition affect measurement stability. Digital compensation and smart transmitter features can extend effective turndown ratios by correcting for these variables in real time.

Control Strategy: Valves, Bypass, and Meter Sizing

Meter selection should not happen in isolation from system design. The overall control strategy, including valve placement, bypass lines, and flow conditioning, plays a major role in achieving effective turndown performance.

Valves: Control valves regulate flow but can introduce turbulence, cavitation, or pulsation that impact meter accuracy. Locating the meter upstream of a control valve typically ensures more stable flow conditions. In systems with significant throttling, consider the valve’s impact on minimum flow and ensure it aligns with the meter’s measurable range.

Bypass Systems: Installing bypass lines allows operators to route low or high flows around a meter during startup or maintenance. In systems with extreme flow variability, a dual-meter arrangement, using a small meter for low flows and a larger one for high flows, can effectively expand total system rangeability.

Meter Sizing: Oversizing is one of the most common mistakes in flow measurement. A meter sized for maximum flow may operate at the lower end of its range most of the time, compromising accuracy. Proper sizing involves analyzing the actual operating flow profile and choosing a meter that measures near the middle of its range during normal conditions.

Balancing these design elements ensures your flow meter operates within its optimal range and delivers reliable data for process control, reporting, and compliance.

Why Turndown Ratio Matters for Performance and Profitability

Inaccurate flow measurement leads to inefficiencies, product loss, and potential safety risks. For industries like oil and gas, where flow measurement affects custody transfer and revenue, small inaccuracies can translate into significant financial loss. A meter with an appropriate turndown ratio ensures that your readings remain trustworthy, minimizing the need for frequent recalibration and reducing downtime.

Moreover, improved rangeability enhances operational flexibility. Systems can adapt to changing process demands without hardware changes, saving both time and money. Engineers can design systems that accommodate both startup and peak flow conditions while maintaining regulatory and quality compliance.

Choose Flowell Corporation for Flow Measurement Excellence

Understanding the concept of flow meter turndown ratio explained is key to achieving accurate, reliable, and cost-effective measurement across variable operating conditions. By carefully considering meter technology, fluid characteristics, and system design, you can ensure that your equipment performs optimally throughout its full range.

For expert guidance and top-quality flow measurement solutions, turn to Flowell Corporation, your premier destination for custom machining and flow measurement products for the oil and gas industry. Based in Tulsa, OK, Flowell Corporation combines three decades of engineering experience with a team of highly skilled professionals to deliver precision-crafted products that meet the most demanding operational standards. Whether you need custom flow components, repair services, or complete system solutions, Flowell Corporation is the trusted name that guarantees excellence in every project.

Contact us today to discover how we can help you achieve superior performance, reliability, and efficiency in all your flow measurement applications.